Not sure if oil or electric heating is right for your roller heat press machine? Find out what fits your print goals, budget, and production style — all in one easy guide.

When I first started helping customers choose heat press machines, one of the most common questions I got was this: “Oil heating or electric heating—what’s better?”

Oil heating provides more stable temperature across the drum, ideal for long runs. Electrical heating heats up faster but may have slight temperature variations. Your production goals decide which is best.

Both systems have their own strengths. Let’s walk through what really matters when making a choice.

Most clients don’t care about the “technical stuff” until it affects print quality or cost. I get it.

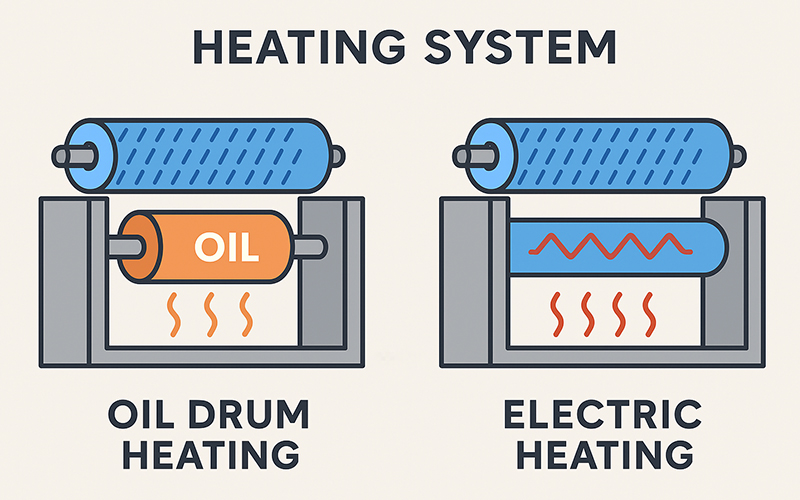

Oil heating uses heated oil circulated through the drum, offering even heat. Electric heating uses internal wires, making it quicker but sometimes less stable.

The oil system works a bit like central heating—it takes a little longer to warm up, but once it’s running, it stays steady. That’s great for long jobs and consistent color output.

Electric heating? Think of it like an electric stove—it gets hot fast. But maintaining a super steady temperature across a large surface? That’s where it can fall behind, especially in wide-format prints.

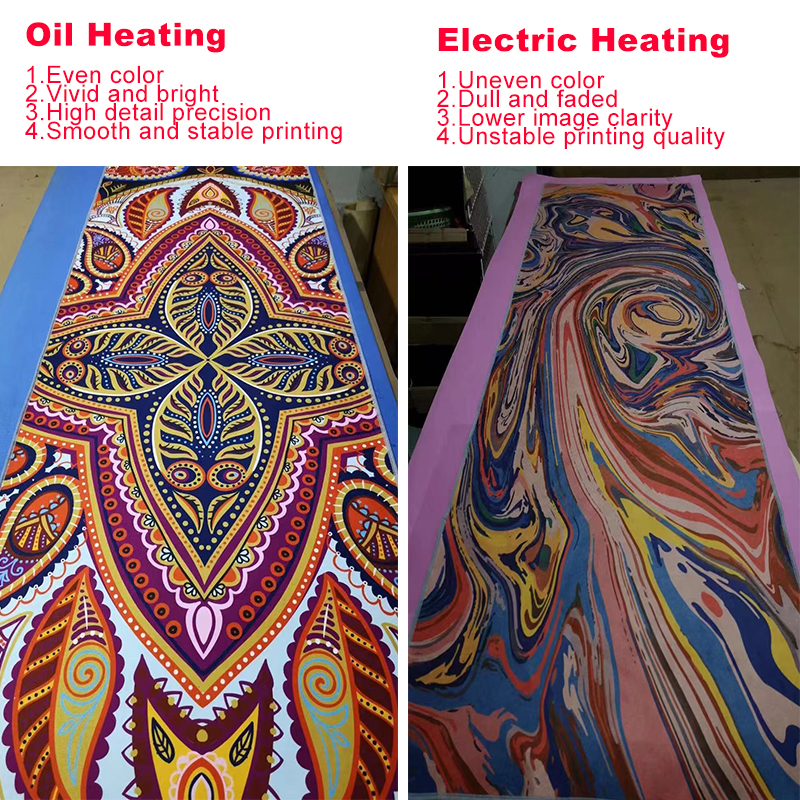

Print consistency depends heavily on temperature. Uneven heat can lead to patchy colors.

Oil heating provides better temperature stability across the roller, which helps avoid color shifts and ghosting during long prints.

In my own experience working with distributors and end-users, the ones printing long banners, bedsheets, or bulk sportswear usually lean toward oil heating systems. Why? Because you don't want your red suddenly looking orange in the middle of a job due to temperature swings.

Time matters. Especially when you’re working on rush orders.

Electric heating heats up faster than oil, making it ideal for quick setups and small-batch printing.

That said, I’ve seen customers make a mistake here—choosing electric just because it starts up fast. But then they scale up, and suddenly, the minor temperature fluctuations start to cause inconsistent prints. Speed is great, but only if it fits your production rhythm.

If you’ve ever stared at a rising electricity bill after running a machine for 12 hours… you’re not alone.

Oil heating is more energy-efficient for long continuous jobs, while electric is better for short, low-volume runs.

Here’s the deal: oil takes more energy upfront to reach temperature, but once it’s hot, it retains that heat efficiently. Electric burns more steadily—and sometimes unevenly—over time. For high-volume shops, oil is usually the better long-term bet.

Let’s talk about upkeep—because nobody wants a breakdown during peak season.

Electric heating systems are simpler and require less maintenance. Oil systems need periodic checks for leaks, temperature controls, and fluid levels.

I've had customers tell me, “Selena, I just want something plug-and-play.” If you’re new to sublimation or have a small team, electric might be the safer start. But if you're running 8 hours a day, 6 days a week? That extra maintenance with oil is worth the performance.

Your machine is only as good as what it produces.

Oil heating offers more consistent heat, which leads to better print quality on large and sensitive materials like chiffon, satin, or bed linen.

If your clients are picky about sharpness and color fidelity, especially on wide-format rolls or fragile materials, I’d definitely suggest oil. It gives that “no-surprises” kind of consistency.

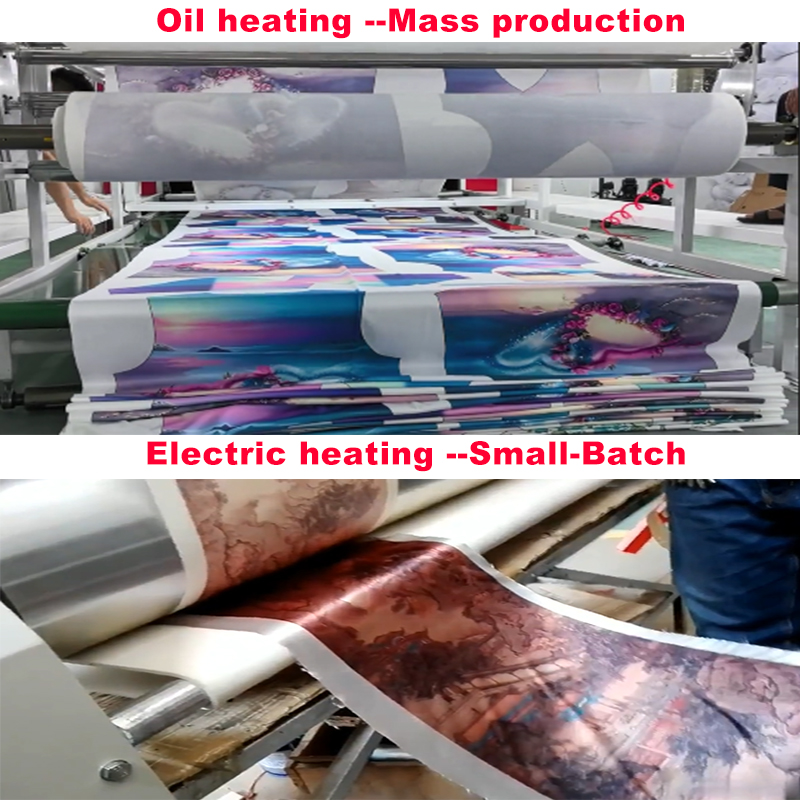

Your production volume should guide your heating choice.

Electric heating suits small-batch, flexible orders. Oil heating is better for high-volume, non-stop production environments.

Some customers do a bit of everything—they start with small orders, then grow into wholesale. In that case, I usually recommend starting with electric, then upgrading to oil once business grows.

And here’s the big question: what does it cost, and is it worth it?

| Heating Type | Initial Cost | Maintenance | Ideal For | Long-Term ROI |

|---|---|---|---|---|

| Oil Heating | Higher | Moderate | Mass production | High (if scaled up) |

| Electric Heating | Lower | Low | Small-batch, low-volume | Medium |

Oil heating machines are more expensive upfront but offer a higher return for large-scale operations. Electric is more budget-friendly for small businesses.

When buyers ask me “Which will help me make more money?” I tell them: it depends on what kind of machine you are today—and who you plan to be a year from now.

Both systems work—but not for the same people. Match your machine to your work style, not just your budget.

Whether you're just starting or scaling up your production, the best heating system is the one that supports your workflow, print quality, and long-term growth. If you’re still unsure, feel free to contact me directly—I’d love to help you find the right fit.

You don’t need to figure it all out alone. Let’s talk, machine-to-human.

Got questions? Contact us to find the best heat press solution for your business.

Contact: Lynne

Phone: +86 135 3266 0169

E-mail: info@flyingheatpress.com

Whatsapp:8613532660169

Add: No.25 Junda Middle Road , Dongkeng Town , Dongguan City , Guangdong Province , China ,523445

We chat